Description

Maxon’s Oil Electro-mechanical NI Series Valves for Hazardous Locations

Maxon normally closed shut-off valves are used in burner system fuel supply lines on industrial boilers, furnaces, ovens, kilns, and other heating processes. All valves are designed to shutoff fuel automatically and instantly with an interruption in the electric power supplied through your safety circuit.

These Honeywell Maxon valves are also used for the manual or motorized opening or closing of pipe lines carrying liquids commonly used in industrial processes. Normally closed valves cannot be opened until the interlocking safety control circuit is proven and resulting electrical power is supplied to the shut-off valve.

All Maxon valves feature one-piece cast iron or cast steel bodies with micro-lapped seats and discs. Straight-through flow path minimizes pressure drop through full open swinging gate bodies.

More Features:

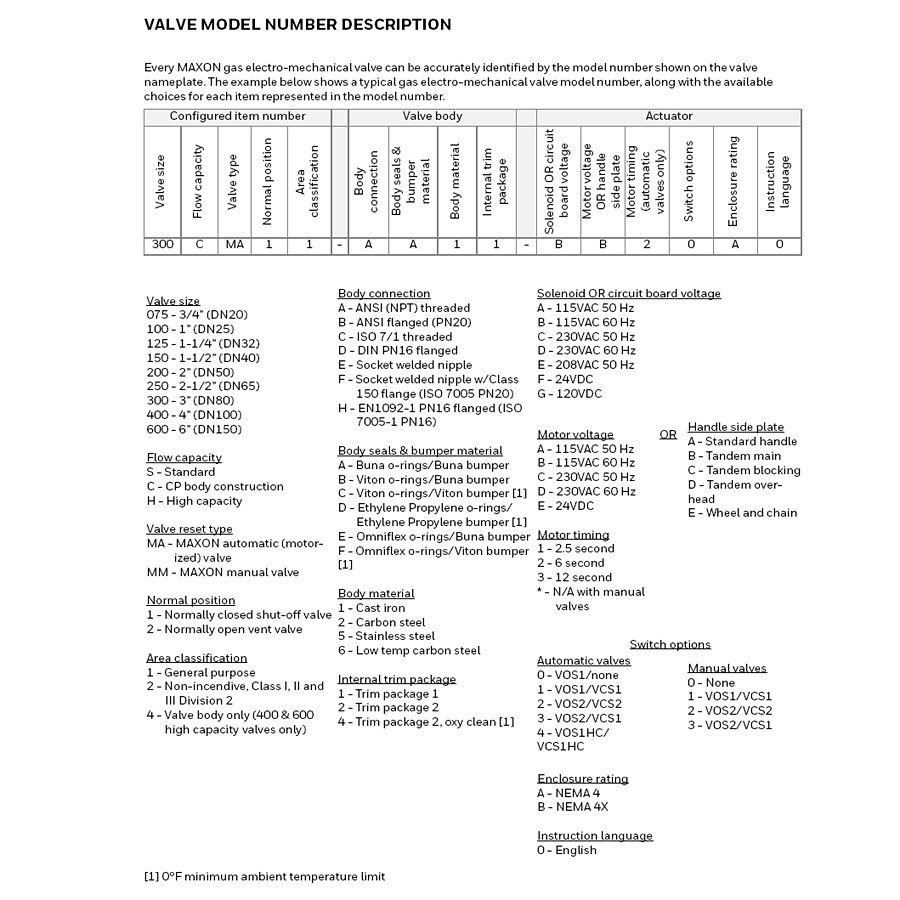

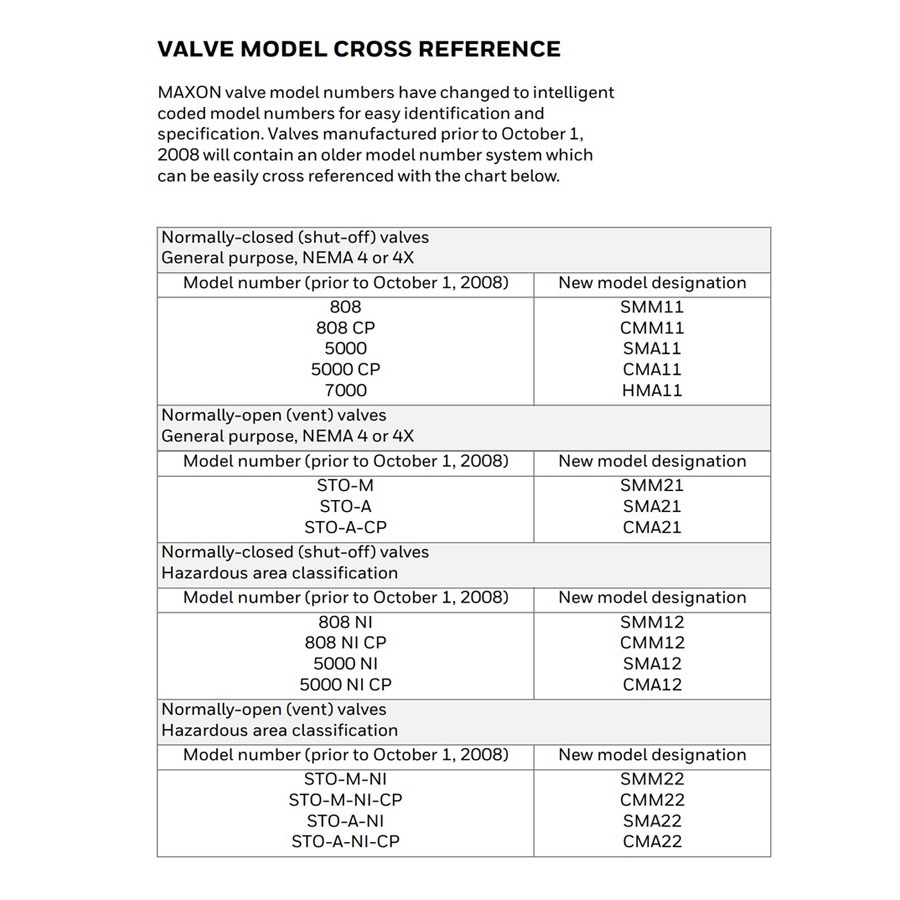

- Honeywell Maxon new model designation – see reference chart and technical documentation

- Handles flowing fluid temperatures: Swinging gate bodies from -20°F (-28°C) to +250°F (+121°C); Any ambient temperature from -20°F (-28°C) to +140°F (+60°C)

- Valve bodies designed to ANSI (American National Standards Institute) standards. ISO (International Standards Organization) standards also available.