Description

Technical

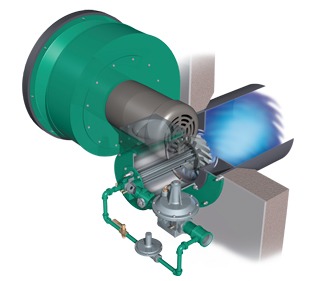

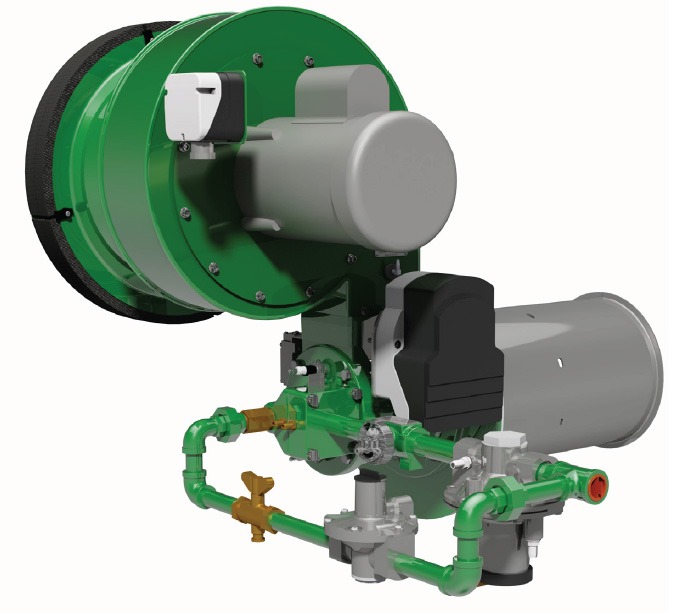

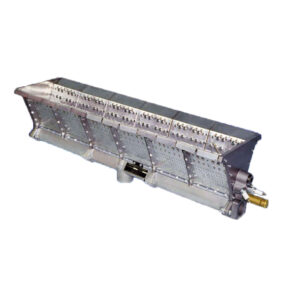

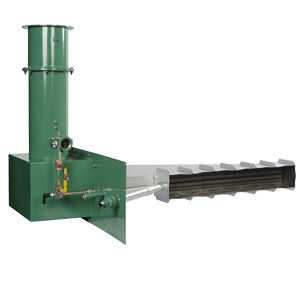

Honeywell Eclipse Winnox Burners are designed to comply with Global Emissions Mandates, easy to set up and operate, and these are low NOx Winnox burners – ideal for air heating and oven applications. Featuring a modular design, a variety of options and configurations are available. Each burner incorporates direct-spark ignition and an air/gas regulator resulting in efficient firing over a wide gas turn down range, all done at a controlled ratio.

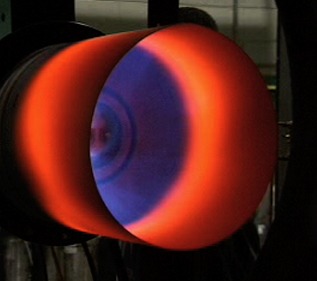

Eclipse Winnox burners feature an intense, short, swirled flame completely contained within the firing tube. The burner nozzle produces an intense mixing of air and fuel, resulting in extremely low emissions.

Winnox burners combine advanced engineering with installation and operational features that are truly world class. These burners have simple, accurate burner control due to integral butterfly valve and ratio-regulator design. Winnox burners are provided with blowers for ease of installation and at 50 Hz. or 60 Hz. for global application. They are also available with alloy tubes or a refractory combustor to meet the demands of customer requirements. Modular design means a variety of options and configurations are available, including NPT or BSP inlet pipe threads.

Application

Typical applications include dry-off and curing ovens, incinerators, indirect air heating, textile drying, food processing/baking, annealing, aluminum homogenizing.

Ask us for engineering or product support to configure your burner.

Eclipse Winnox Burners with packaged blower:

WX0050 Maximum Input, 168,000 Btu/hr. (49 kW), 60 Hz

WX0100 Maximum Input, 1,130,000 Btu/hr. (333 kW), 60 Hz

WX0200 Maximum Input, 2,270,000 Btu/hr. (667 kW), 60 Hz

WX0300 Maximum Input, 3,360,000 Btu/hr. (980 kW), 60 Hz

WX0400 Maximum Input, 4,460,000 Btu/hr. (1310 kW), 60 Hz

WX0500 Maximum Input, 5,560,000 Btu/hr. (1630 kW), 60 Hz

WX0600 Maximum Input, 6,690,000 Btu/hr. (1960 kW), 60 Hz

WX0850 Maximum Input, 9,700,000 Btu/hr. (2840 kW), 60 Hz